Varnishing vs. Laminating Labels:

Which Finish is Right for You?

When it comes to high-end label production, the finish is just as important as the design. It’s what protects the label, enhances its appearance, and influences how it feels in the customer’s hands. Two of the most common finishing techniques are varnishing and laminating, but which one is best for your labels? Let’s break down the differences and explore how either can take your labels to the next level.

What’s the Difference Between Varnishing and Laminating?

The key difference is in the application process and the level of protection each provides:

Varnishing is a liquid coating applied to the label surface. It dries or cures to form a protective layer, enhancing durability and visual appeal. Varnishes can be glossy, matt, satin, soft-touch, or textured, with the option for spot varnishing to highlight specific areas of the design.

Laminating is the process of applying a thin film over the entire label. This film provides a thicker, more durable layer of protection, making the label highly resistant to moisture, scratches, and chemicals. Laminates also come in different finishes, including gloss, matt, soft-touch, and anti-scuff.

When to Choose Varnishing

✅ Best for paper-based, eco-friendly materials

✅ Offers cost-effective protection

✅ Allows for spot finishing to highlight elements

✅ Ideal for premium and luxury branding

When to Choose Laminating

✅ Provides superior durability and moisture resistance

✅ Best for industrial, pharmaceutical, or refrigerated products

✅ Creates a high-end, tactile experience (soft-touch laminates)

✅ More resistant to abrasion and harsh conditions

Exploring Different Types of Varnishing

Gloss, Matt & Satin Varnish

- Gloss varnish makes colours pop with a shiny, reflective finish.

- Matt varnish creates a soft, premium aesthetic.

- Satin varnish offers a balance between gloss and matte for a subtle sheen.

Soft-Touch & Textured Varnish

- Soft-touch varnish gives labels a velvety feel, perfect for luxury branding.

- Textured varnish adds a unique tactile effect, making the label more engaging to the touch.

Spot Varnishing

- Precision enhancement

- Applied only to specific areas of the label, spot varnish creates a contrast in shine and texture.

- Ideal for highlighting logos, patterns, or key design elements.

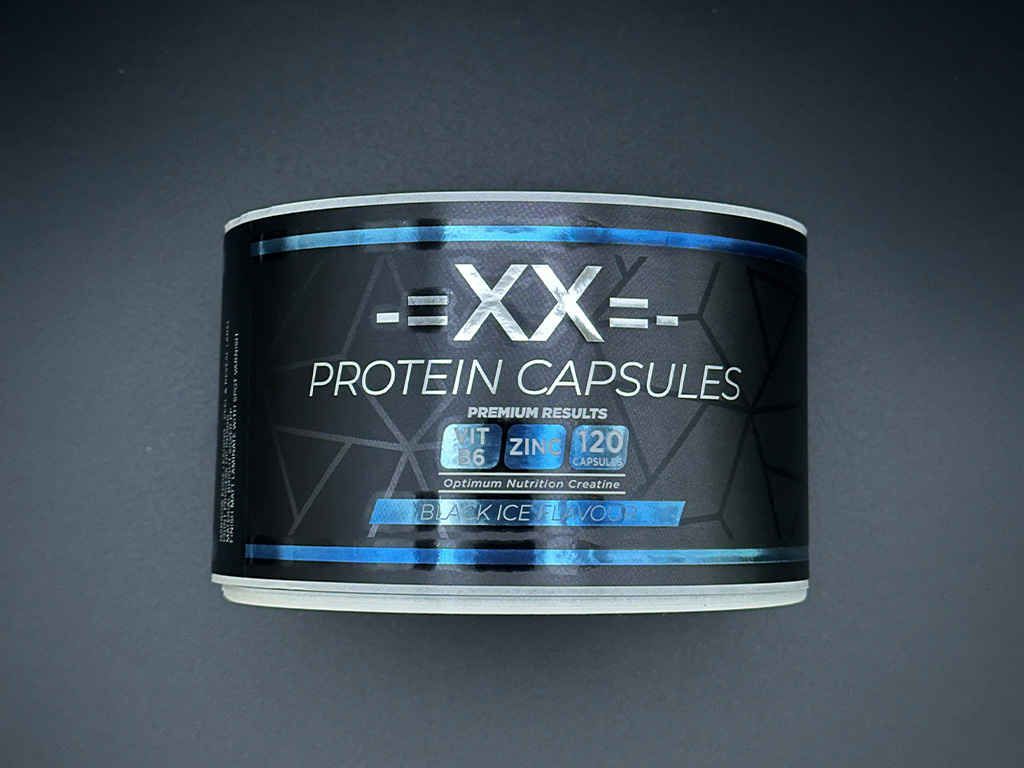

Silkscreen Varnishing: Elevating Labels to the Next Level

Unlike standard varnishing, silkscreen varnishing applies varnish in thicker layers, creating a raised, textured effect. This process enhances visual contrast and tactile engagement, making it perfect for premium labels in sectors like cosmetics, luxury spirits, and high-end food products.

Key Benefits of Silkscreen Varnishing

✨ Adds a raised, tactile effect

✨ Creates high-definition textures that can make labels stand out

✨ Provides extra durability against scratches and moisture

✨ Allows for braille applications or enhanced tactile branding

DigiJet: Digital Varnishing

At Bakers we also offer digital embellishments – varnishing and foiling using our DigiJet module on one of our ABG Series 3 Digicons. Precision, detailed spot and high build varnish to highlight key design elements of your labels, without requiring additional tooling. This gives the added benefit of speed to market and variability across multiple SKUs in the same order. Discover more by asking for our digital embellishment label sample pack.

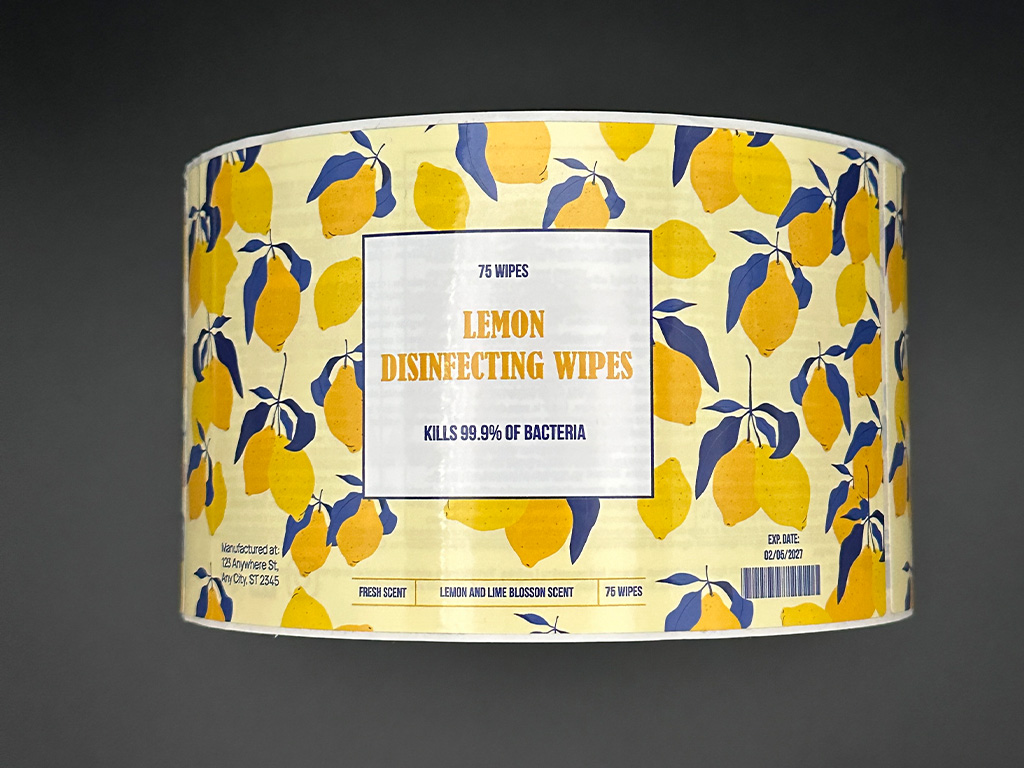

Laminating Labels: A Deep Dive

Laminating offers an extra level of durability, making it a go-to choice for labels exposed to harsh conditions.

Gloss Laminate

Bright and reflective, enhances colours and vibrancy.

Matt Laminate

More muted and elegant, giving a premium look.

Anti-scuff laminate

Designed for high-contact environments where labels need extra protection.

Soft-touch laminate

Velvety, non-reflective finish that adds a luxury feel. Often used to contrast with a bright foil embellishment or raised spot varnish.

Industry Applications: Varnishing vs. Laminating

Industry

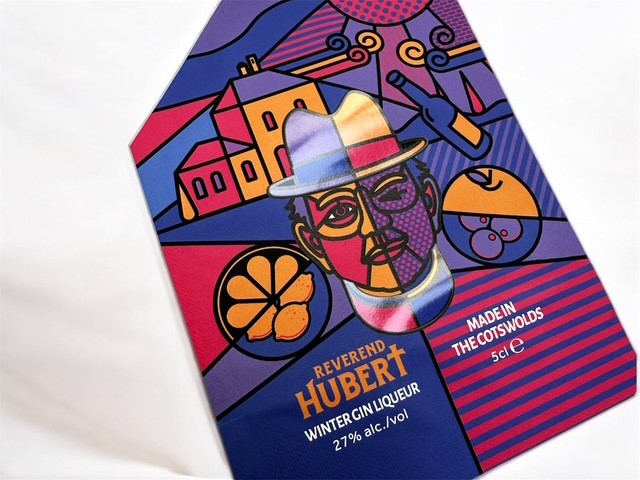

- Luxury Goods (perfume, high-end drinks)

- Food and Beverage

- Pharmaceuticals & industrial labels

- Eco-friendly brands

Recommended Finish

- Silkscreen varnishing, soft-touch finishes

- Gloss / matt varnish or lamination for durability

- Lamination for chemical / moisture resistance

- Varnish with a reduced plastic content

Sustainability Considerations: Which Option is Greener?

Laminates are typically harder to recycle because they add an extra layer of plastic. However, new biodegradable and recyclable laminates are now available. On the other hand, varnishing—especially UV or water-based varnishes—offers a more eco-friendly option. Brands looking for sustainability should consider these alternatives while still achieving a premium look and feel.

Digital Embellishments

Creating high quality, embellished labels without the need for plates and tooling is a sustainable option. Less waste and highly efficient for shorter runs or multiple versions. Read more

Choosing the Right Finish for Your Labels

The best finish depends on your product’s environment, branding goals, and durability needs. If you want high-end tactile effects, varnishing (especially silkscreen varnish) is a great option. If maximum durability is needed, lamination is the way to go.

Varnish vs Laminate FAQs

What are the main differences between varnishing and laminating in label production?

• Varnishing is a liquid coating applied to the label’s surface, which then dries or cures to form a protective layer. It can be glossy, matte, textured, or spot-applied for design contrast.

• Laminating is a physical film that is applied over the label, creating a thicker and stronger barrier. It also comes in gloss, matte, soft-touch, and other finishes.

The main difference is that varnish is applied as a coating, while laminate is a film layer.

What role does varnishing and laminating play in label production?

Both varnishing and laminating are essential finishing processes that protect labels, enhance their appearance, and influence how they feel to the touch. They help improve durability, ensuring the print doesn’t fade, scratch, or deteriorate over time. They also play a big role in branding, helping products stand out with different finishes like glossy, matte, soft-touch, or textured effects.

How does the application process differ between the two techniques?

- Varnish is applied as a liquid via a roller or screen and then dried using UV light or air drying.

- Lamination involves pressing a clear film onto the label surface using heat and/or adhesive.

Do certain materials work better with varnishing vs. laminating?

- Yes! Glossy and coated materials take varnish well because they allow for a smooth, even application. Uncoated or textured materials may absorb varnish unevenly. Lamination is also preferable when a stronger, more protective finish is needed, such as for products exposed to moisture or chemicals.

What are the cost implications of varnishing vs. laminating?

Varnishing is usually more cost-effective, while lamination is more expensive due to the extra material and processing.

What finishing techniques work best for brands looking to balance premium aesthetics with eco-friendly materials?

Using UV varnish or recyclable soft-touch laminates helps brands maintain a luxury feel while staying sustainable.

How does silkscreen varnishing differ from standard varnishing?

- Silkscreen varnishing is a thicker, more textured application compared to standard varnish. It uses a mesh screen to apply varnish in raised layers, creating a tactile, high-end effect that you can feel. It’s great for adding spot detailing, Braille, or embossed effects.

Are there any technical limitations or challenges with varnishing?

Yes, varnishing may not be as durable as lamination when exposed to harsh environments, chemicals, or excessive moisture. It also depends on the material—it doesn’t always adhere well to highly textured or uncoated papers.

What are the different types of laminate available?

• Gloss laminate – Bright, reflective, and eye-catching.

• Matte laminate – More muted and premium in appearance.

• Soft-touch laminate – Feels velvety and luxurious.

• Anti-scuff laminate – Designed for durability in high-contact environments.

Is lamination more suitable for certain industries or environments?

Yes, food & drink, cosmetics, pharmaceuticals, and industrial labels often require lamination for added protection. Lamination is also essential for labels exposed to extreme conditions, like refrigeration or outdoor use.

When would you recommend varnishing over laminating, or vice versa?

• Use varnishing when you want a subtle, elegant finish or when printing on paper-based, eco-friendly materials.

• Use lamination when extra durability, moisture resistance, or a high-end soft-touch feel is needed.

How do sustainable finishing options compare to traditional varnishing and laminating techniques?

• Water-based and UV varnishes are more eco-friendly than solvent-based alternatives.

• Some laminates are now made from biodegradable or recyclable materials, reducing environmental impact.

Choosing between varnishing and laminating is all about balancing aesthetics, protection, and functionality. If you’re after a premium, tactile experience with selective highlights, varnishing—especially silkscreen varnishing—can add real depth to your design. But when durability and resilience are key, lamination provides that extra layer of defence. At Bakers, we help our customers find the perfect finish to make their labels both stunning and practical.

Need Expert Advice? Let's Talk!

At Bakers, we specialise in high-quality label finishing techniques that enhance your brand. Whether you need varnishing, laminating, or a combination of both, we’ll help you find the perfect solution.

Read more about other label finishing options