Independent Label Production House

Our state-of-the-art factory hosts multiple label print and finishing pressesThrough the decades, investment in the latest printing technology and equipment as well as highly skilled operators has kept Bakers at the forefront of the label printing industry. We operate with a range of top quality label presses, giving us the freedom to choose the best technology to produce optimum labels for your specific application. All presses are reel to reel with either inline or offline finishing and sheeting.

Digital Printing

The HP Indigo 6K+Digital Press is the market-leading narrow-web printing solution for digital labels and packaging production, delivering high productivity, wide versatility, and intelligent colour automation. At Bakers we now operate with 2 HP Indigo 6K+ presses running side by side to provide new capabilities. The presses use the indichrome system, which is orange, violet and green as well as the conventional four colours CMYK; this gives a wider gamut of colour when reproducing pantone colours. The press also has a white channel for clear substrates but we can also add spot colours and specials such as fluorescent pink, silver or invisible blue and yellow. The HP Indigo 6K+ offer pioneering SmartStream Mosaic and Collage software allowing every label imagery to be unique – a commercial capability that our customers will truly be able to benefit from. In addition it facilitates synchronisation across all digital processes enabling greater consistency through small, medium and large print runs. The multi-threaded RIP reduces lead times whilst increasing productivity.

Specification:

Max web 330mm Max Print area 320 x 980mm

12-450 microns supported substrate thickness

Max colour print speeds of up to 40m/min

Inkjet Presses for Label Production

Specification

Resolution 1200 x 1200 dpi

Maximum web width 350mm

Maximum print width 338mm

Printing speed 80m/min

Durst Tau RSC 340 LED

The Durst Tau RSC 340 LED label press represents cutting-edge technology in digital label printing, now part of Baker Labels’ equipment lineup. Known for its precision and efficiency, the press features 1200 x 1200 dpi resolution with advanced Fuji Samba print heads, enabling exceptional print quality. Its CMYK+White LED inks deliver vibrant colors and versatile printing options, with speeds up to 80 meters per minute for CMYK and 52 meters per minute with white ink.

Designed for versatility, the press supports materials from 160mm to 350mm in width and features a robust internal system, including unwind/rewind, web cleaning, and tension controls. Enhanced user-friendly elements, such as the auto start-up timer and an intuitive interface, further streamline operations.

With its ability to rival traditional analog printing and provide excellent job transferability from Indigo presses, the Durst Tau RSC 340 is a game-changer for label printing at Baker Labels

Specification

Resolution 600 x 600 dpi

Maximum web width 350mm Maximum print width 322mm

Printing speed 50m/min

Truepress Jet L350 UV

The Screen inkjet along with the Durst press complement the Indigos. They are faster, with excellent up-time and eat the work, with a very good white for clear and silver stocks. High pigmented colours with a combination of advanced print heads & screening can produce smoother gradations resulting in truly stunning photo quality detail that’s up to 600 dpi at a top speed of 50m p/m or 30m p/m with white.

Ideal for top quality high scuff resistant products on multiple substrates with possible savings on over-laminates or even varnishing. We have introduced fully variable capability on the machine, now able to print complex multi-page PDFs. The UV cured ink has a much higher build than the Indigo with the result being more of a screen label look than litho with very wide colour gamut, giving a high gloss, durable and lightfast result with great scratch resistance. This precision label press is ideal for producing detailed dot codes such as QR and barcodes, as well as any other security printing requiring a high level of accuracy.

Flexo printing

Nilpeter FB-3

The printer of choice for larger runs and for complex multi-layer, multi pass constructions. Featuring a rail system which contains De-Lam/Re-Lam, turner bar, 4 towers for over-laminating substrates and a crossover unit. We have also installed a servo re-insertion unit with web guide and a corona plus a rotary screen unit for embellishments, fluorescents etc.

The dual axis servo transport system ensures that the FB-3 will continuously deliver the highest level of print reproduction as well as unparalleled registration performance.

We’ve also installed a new rotary screen unit – the first one to be fitted to a FB3 Nilpeter. The main plan for the Stork unit is for re-registering work from the digitals to give high build and tactile effects but there are also opportunities to do more specialist work.

Specification

Eight Colour UV Flexo

Max web width 350mm

Press speed 228m/min

2 rotary die heads

1 rotary sheeting head

Finishers

ABG Digicon Series 3

2 Flexo heads, Big Foot hot foil/embossing unit, 2 laminating stations, flat bed silkscreen, flyeVision, die cutting and auto slit knives. Max web 330mm

ABG Digicon Series 3

Flexo, overlam/cold foil, DigiJet, die cutting, flyeVision, auto slit knives and in-line turret rewinder. Max Web 330mm

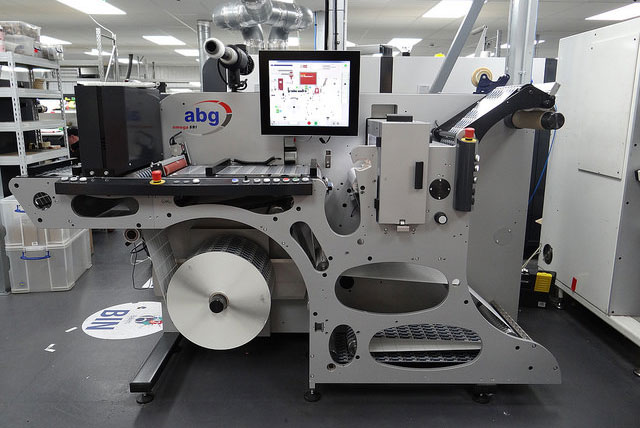

Omega Digicon Lite 1

Corona, UV Flexo, overlaminating and diecutting. Maximum web width 330mm

Omega Digicon Lite 3

Corona, UV Flexo, overlaminating and diecutting. Maximum web width 330mm

Rewinders

We use both the HSR330 Rewinder and the Omega SRI Rewinder – the new generation of label converting and finishing with rewinding speeds of up to 350m/min. Fully integrated FleyeVision 100% inspection control with screen operation, connected with an integrated work flow for waste management. The SRI range uses the latest servo drive technology combined with PC/SPS based control resulting in a new level of sophistication to meet today’s ever increasing demands. In February 2018 we also installed an Auto Set Vectra SGTR glueless turret rewinder from AB Graphics.The Vectra SGTR holds the substrate to the cores at the start of a new roll without stopping or slowing down the converting equipment. In addition, it is fitted with a print and apply label applicator to close the finished roll with a label. Quick, fast and clean, it is especially suitable for rewinding labels which have been printed on heat sensitive substrates, or using heat sensitive inks, finishes or decorations.

and the rest…

GM ETV330 High Speed Sheeter

Roll to sheet guillotine cutter suitable for cutting labels and heavy materials.

Typical speed 3000-10,000 sheets/hour, subject to the job.

Roland DG Versa UV LEF 300

Matrix Laminator

2 x ABG Omega RTS330 Sheeter

The RTS can achieve running speeds of 40m/min for an A4 size sheet producing 150 labels a minute.

AutoSet Vectra SGTR

With fully automatic changeover, the new AutoSet Vectra SGTR saves hours of costly set up and changeover time.

T450 Shrink Wrap

2 x ABG Omega SR270 Slitter Rewinders

1 x Ricoh Pro C7200x

Roland Soljet Pro III

Studio

At Baker Labels our talented and experienced in-house studio team work with the artwork designs our customers send us to ensure they are perfectly prepared for the presses.

Technical capabilities

Our studio team work on Apple’s high-performance Mac Studios. This allows them to use the most current industry standard software including Hybrid Packz and Adobe Creative suite.

We’ve linked GMG ColorServer Multicolor and Hybrid CloudFlow with our custom MIS system to automate the more repetitive parts of our workflow. This takes the mundane tasks off our team’s plate, giving them more time to focus on what they’re great at—perfecting and double-checking your designs.

Our studio utilizes a high-end toolkit to ensure total precision:

Automation & VDP:

We use Hybrid Cloudflow/Packzflow, Esko Dynamic VDP, HP SmartStream Designer and Packz VDP Execute to automate bespoke label production, including complex barcodes and QR codes.

Colour Control:

GMG ColorServer maintains strict colour consistency, ensuring your brand and spot colours meet exact standards every time..

Internal Proofing:

Using GMG ColorProof alongside our Epson P7500 and S80600 proofers, we verify colour accuracy in-house across various materials—including silver and clear—before any job moves to production.

Colour management & prepress

Baker Labels provides a comprehensive prepress service designed to deliver accurate, consistent colour reproduction across all devices. This includes the setup and ongoing management of brand colour profiles to ensure your colours remain true and consistent from proof to print.

Our colour management systems align colour spaces across devices, guaranteeing reliable and repeatable colour results at every stage of production.

Colour accuracy is verified using industry-leading technology, including the X-Rite eXact 2 spectrophotometer, X-Rite i1PRO, iO table, and GTI viewing light box. Our Colour Management System is powered by GMG Colorserver Multicolour solution, fully integrated with Hybrid Cloudflow and connected to our purpose-built MIS system.

Contract-quality proofs are produced on Epson SureColor P7500 and S80600 proofing systems. This enables automated colour control, remote proofing capabilities, and highly consistent, repeatable colour matching you can trust.

Artwork specification

We accept a wide range of file types. For best results, a vectorized PDF is preferred.

White Label Despatch

We recognise the importance of a confidential service for trade customers and you can count on our integrity as a trade supplier to avoid any conflicts of interest.

All orders are delivered to customers under plain cover or with your own branded delivery notes if requested.

Our Despatch Team will wrap, and package your orders to the highest standards and ship out efficiently to ensure you and your customers receive the best service possible.

UK Distributor of Label Materials

Bakers are also the leading independent distributer of self-adhesive and non-self-adhesive label materials in the UK.

Offering a comprehensive range of both branded and non-branded label products, we are a “one-stop shop” for the roll label printer. If your customers require samples of materials from the huge stock we carry, we can send them for next day delivery.

Need to order labels?

Speak to our friendly team to discuss your label requirements or give us some basic information on our enquiry form and we’ll be in touch.