The Art of High-End Label Production

Mastering the Craft of Premium Labels

Why Choose High-End Labels?

In this post, we’ll walk you through some of the most popular techniques we use to create premium labels, including embossing, debossing, hot and cold foiling, and the show-stopping unifraxion foiling. These processes add texture, depth, and even holographic effects, transforming a simple label into something truly memorable.

Our Technical Processes

Embossing and Debossing: Adding Depth to Your Design

What’s the Difference?

The choice between embossing and debossing really depends on the vibe you’re going for. Embossing pops, while debossing is more understated.

Both processes require creation of “male” and “female” dies of the design and meshing them together into either side of the material with enough pressure to create a crimp. Like how cogs mesh. These dies can be made of a hard polymer, a metal, or a combination of both and will add a premium feel to a label, particularly suited to industries like luxury goods, wine, or cosmetics, where a tactile quality really matters.

Embossing

When we talk about embossing, we’re referring to the process of raising a design off the surface to give it a textured, 3D effect. Imagine running your fingers over the label and feeling the design—it adds a tactile quality that really makes your label stand out.

Debossing

On the flip side, debossing is when we press the design into the material, creating an recessed effect. It’s a more subtle way to create texture, and it’s often used for brands that want an understated, yet elegant, finish.

When to Use Them

Embossing is ideal for luxury products like wines, cosmetics, or high-end food packaging, where creating a standout look is essential. Debossing, on the other hand, is fantastic when you want a more understated elegance.

To get perfect results, we carefully control the pressure and temperature during embossing and debossing. Intricate designs can be tricky because if the die isn’t precise or the material’s too soft, the details might not come out clearly. Embossing and debossing will benefit from sturdier papers or premium stocks that can hold the raised or indented shape well. We take extra care at design stage to ensure all elements align to enable top quality results.

Hot and Cold Foiling: A Shiny Touch of Luxury

Hot Foiling vs. Cold Foiling

Hot Foiling

Hot foiling adds the luxurious metallic touch you often see on premium labels. It involves a heated die pressing foil onto the label material. The combination of heat and pressure ensures only the foiled image adheres to the substrate, creating a shiny, reflective effect.

Cold Foiling

When to Use Them

If you’re looking for that ultra-premium look, hot foiling is your go-to. Think perfume bottles, premium spirits, or luxury chocolates. Hot foiling is perfect for adding high quality finishes to luxury products, especially on wine stocks where the open fibres of the substrate make cold foiling very challenging.

Cold foiling is a good option for large production runs for food and beverage labels or cosmetics when you need something eye-catching and cost effective, but you would need to consider the artwork design and printing stock when deciding the best process to opt for. Cold foiling is also the foiling option for our digital embellishments.

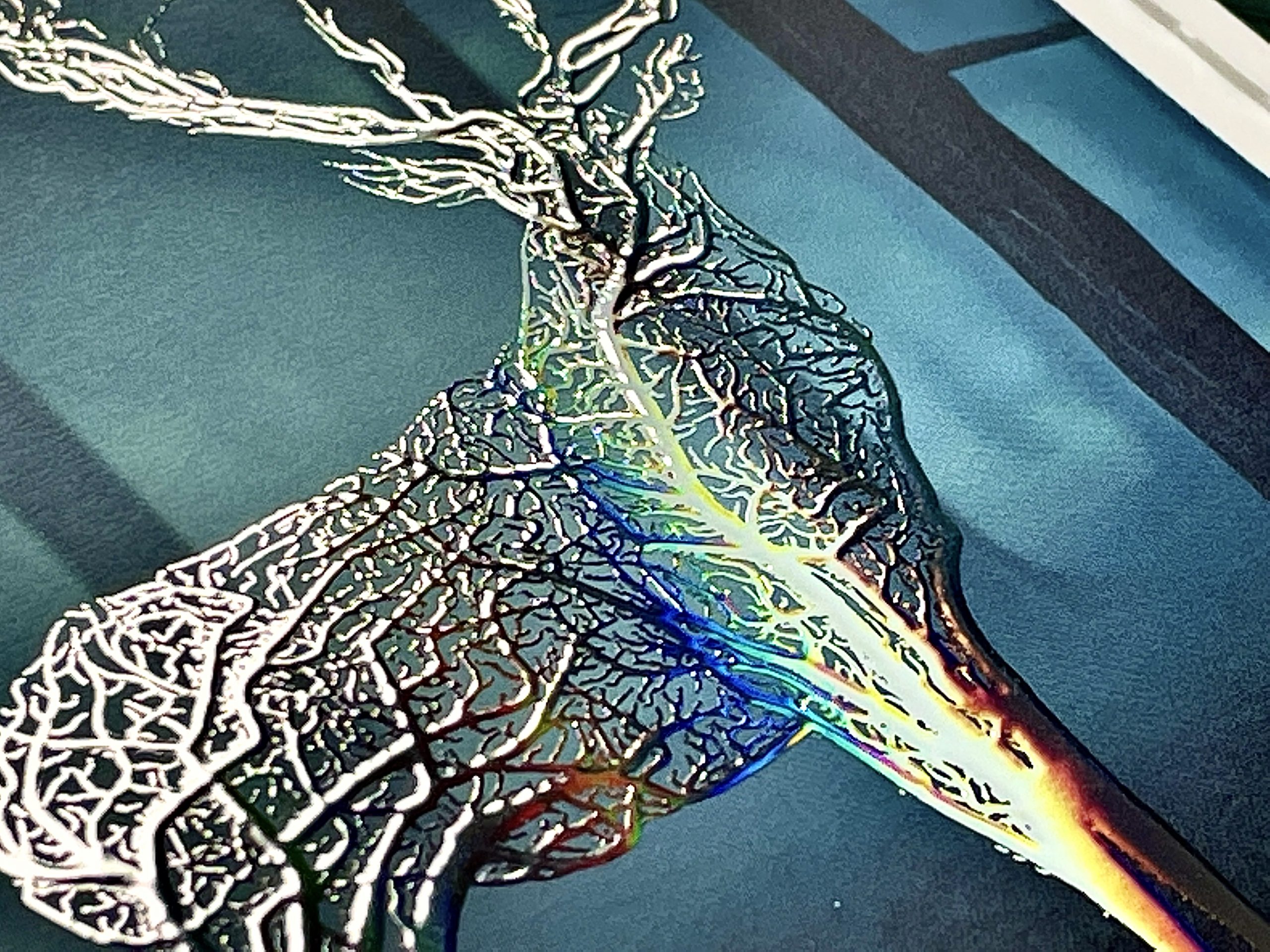

3D Foiling: Bringing Your Labels to Life

Looking for something truly next-level? Hot foiling with dynamic, 3D effects that shift as you change your viewing angle. This technique layers foil in a precise way to give the illusion of movement or depth, making it perfect for products that need to grab attention, such as electronics, premium drinks, or toys.

3D Foiling

3D foiling involves layering multiple images or designs to create an illusion of depth and movement. It’s a unique graphic alternative that uses metallic hot stamping foil and fine engraved line patterns to impart definition to your images. This kind of hot foiling grabs attention and skyrockets a product’s shelf appeal. The 3D process brings new depth, light and movement to your label and packaging designs.

Combining Techniques for Maximum Impact

The processes are all interchangeable. For example, you can combine foiling with embossing for a more complex, layered effect, or use different foil colours to match specific branding. Some designs and materials may require special handling so for any unusual requests, we collaborate closely with our clients to figure out the best combination of techniques to meet their specific needs.

Watch a behind the scenes production video of the 3D foiling process in action on YouTube

Digital Embellishments: The Sustainable Option

Over the past few years, we’ve seen digital embellishment growing in popularity. By combining digital technology with traditional methods like embossing and foiling, we can create, and process intricate designs over multiple SKUs faster and more cost-effectively, especially for small runs. With sustainability a constant focus of many brands, high-end labels need to not only be eye catching, but also eco-friendly. Digital embellishment aids production sustainability by reducing set up times, material wasted, and negating the requirement of manufactured solid tooling. Watch on YouTube

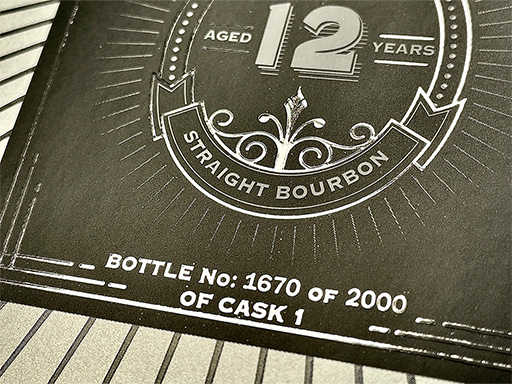

Digital Foiling

Digital foiling is only possible thanks to our A B Graphic Digicon Series 3 and its DigiJet module. It uses image files rather than tooling to create the cold foiled details, so it’s perfectly suited for the high speed turnarounds many customers demand. Without compromising on quality, digital foiling is an excellent option for label orders with multiple variations (such as foiled cask numbers).

Digital Spot and High Build Varnish

For a more subtle effect, a background varnish area can give the illusion of a textured material.